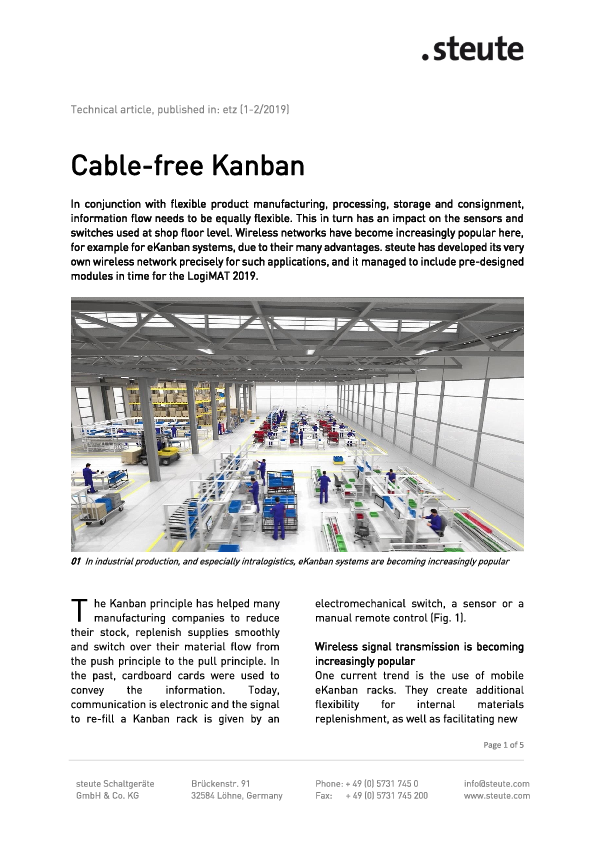

Cable-free Kanban

In conjunction with flexible product manufacturing, processing, storage and consignment, information flow needs to be equally flexible. This in turn has an impact on the sensors and switches used at shop floor level. Wireless networks have become increasingly popular here, for example for eKanban systems, due to their many advantages. steute has developed its very own wireless network precisely for such applications, and it managed to include pre-designed modules in time for the LogiMAT 2019.

Source: etz (1-2/2019)